Long-term behaviour of fuel assemblies in storage during significantly longer storage periods

For example, the fuel rod cladding tubes are exposed to stresses during the entire period of dry storage. They are under high internal pressure, subject to radioactive radiation, and they cool down only slowly due to the decay heat. This raises the question as to whether the material properties can deteriorate under these boundary conditions.

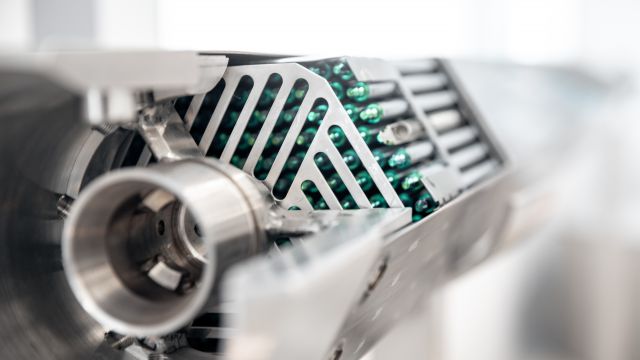

Fuel assemblies contain the nuclear fuel that is fissioned in a controlled manner in a nuclear power plant (NPP). After some time, the fuel assemblies are “spent” and will be replaced by new ones. The spent fuel is high-level radioactive waste, which in Germany is intended to be disposed of in a repository in deep geological formations. Until such a repository is found, the fuel is stored in storage facilities in special transport and storage casks.

Even though the search for a repository has begun, it will probably take decades before the fuel can be transferred. However, the licences for the storage facilities and the transport and storage casks will expire between 2034 and 2047, depending on the site, so that they need to be extended beyond this period. For this purpose, reliable technical and scientific findings are indispensable that prove that all safety requirements are fulfilled, even if the spent fuel is stored much longer than provided for according to the existing licences. In addition, the transport and storage casks have not been designed for disposal yet, so the fuel assemblies must be transferred from the transport and storage casks into special disposal containers. To do this, they must be handled mechanically and must also be sufficiently stable.

Research team takes a three-step approach

The scientists have therefore developed a computer code that can be used to answer open questions about the condition and behaviour of fuel assemblies during long-term dry storage. In addition to performing their own calculations, they also developed computer codes that they implemented in already existing software programs such as KENOREST, TESPA-ROD or the freeware COBRA-SFS. To achieve the desired results, three successive steps were necessary, namely

- determining the current condition of the nuclear fuel,

- calculating the temperature development inside the casks, and

- determining the fuel rod behaviour.

In the first step, the UO2 and mixed-oxide fuel rods commonly used in Germany had to be characterised, including, among other things, the calculation of the burn-up and the resulting decay heat output.

In the second step, appropriate cask models were developed for the computer codes. The values determined in Step 1 and the resulting temperature fields were analysed over the time of storage. In the third step, the research team developed and implemented models to simulate the fuel rod behaviour. Here, the chemical, thermal and mechanical interactions between fuel and cladding tube are of particular importance.

The applications and computer codes required for the solution of the individual steps for burn-up and decay calculation, for determining heat generation and propagation as well as the cladding tube behaviour are coupled to form a kind of manual calculation chain. The future goal is a calculation chain that can be operated from a single program/interface.

Further investigations required

In addition to a multitude of findings, the work also raised new questions of detail, for example as to the degree of influence of a slow temperature decrease in the cladding tube on the hydrogen dynamics in the cladding tube. Hydrogen is present in every cladding tube due to oxidation processes and forms fine hydrids at concentrations above the solubility limit, which disturb the surrounding metal lattice and lead to embrittlement.

Furthermore, the robustness and validity of the results of a calculation chain for predicting the behaviour of the irradiated material for long periods of time (more than 40 years) must be further enhanced. On the one hand, this is due to the fact that there is hardly any direct validation possibility for the fuel rod behaviour over these periods of time since casks that have already been filled would have to be opened and their contents subjected to material tests. On the other hand, these are multi-physical simulations with cross-scale models ranging from microscopic-atomistic simulation to macroscopic simulation of the entire cask. A detailed uncertainty and sensitivity analysis of the results is therefore necessary for a better assessment and robustness of the results.

Project highlights Storage

Das Projekt zielte darauf ab, Methoden für die Analyse des Brennstabverhaltens zu entwickeln.