PROST: Analysing the structural reliability of components

Pipes and vessels under continuous loads

Safety-relevant components in nuclear installations must maintain their integrity over the entire service life. They must withstand, for example, high internal pressures, temperature fluctuations, vibrations, neutron irradiation and chemical processes. These impacts and also the smallest cracks that can occur during manufacture or during operation are taken into account in a conservative manner when designing and dimensioning the components. To demonstrate that no crack growth can occur that may compromise integrity, appropriate analyses must be carried out. PROST investigates both the process of crack formation and the growth of postulated cracks using widely recognised fracture mechanics models and taking specific ambient conditions into account. The simulation code can also be used to assess whether the development of a crack to a leak or even break of the component can be precluded for a certain time.

Multiple damage mechanisms

PROST can simulate the growth of crack-like defects due to corrosion, material fatigue (as a result of cyclic loads) and ductile crack growth (ductile fracture under large loads); the combination of multiple damage mechanisms is also possible. For each damage mechanism, several models are available that describe the behaviour of the material in the specific case. The growth of through-thickness cracks (leaks), from which for example coolant escapes, can also be simulated with PROST and the safety margin to component failure quantified.

Objective: Assessment of findings and determination of reliability

PROST can be used, on the one hand, for the fracture mechanics assessment of a real finding made e.g. during a non-destructive test. Here, the main question is whether the integrity of the component is still fully ensured (deterministic analysis). On the other hand, the reliability of a component can be determined, i.e. statistical fluctuations in the material properties and in the assumptions regarding the mechanical loads are taken into account. In this case, PROST calculates the leak and break probability as a function of the operating time (probabilistic analysis), also allowing to quantify the influence of individual parameters on the failure probability.

Validation and examples of application

PROST has been validated in various test cases. Probabilistic test cases were successfully calculated, among others, in the international benchmark NURBIM (EU) and in the Finnish-Swedish NKS study. Currently, GRS participates in a benchmark of the International Atomic Energy Agency (IAEA) and one of the Nuclear Energy Agency of the Organisation for Economic Development and Co-operation (OECD/NEA). The deterministic capabilities of the code were demonstrated, among others, in the international benchmark BENCH-KJ (OECD).

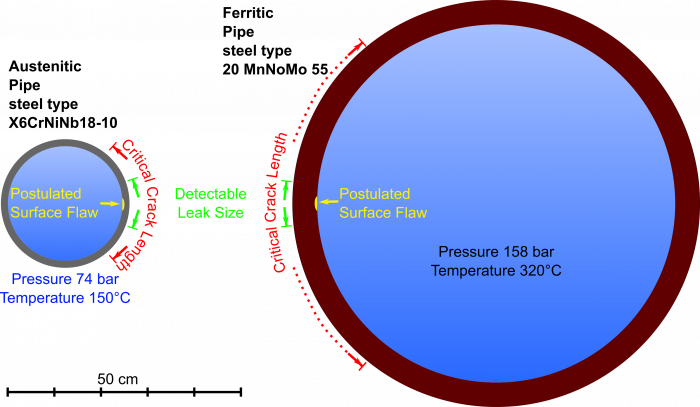

PROST has contributed to answering numerous fracture mechanics questions related to pressurised and boiling water reactors. In addition, the code could help in the implementation of the “leak-before-break” concept, which has been further developed in Germany and is also used internationally (see Fig.). Here, it is demonstrated that a leak is detected at an early stage and countermeasures can be taken before a break occurs. The main influencing parameters for the leak-before-break behaviour and the reliability of components with proven break preclusion were also determined with PROST.