10 Years of Fukushima Part 3: Dismantling

It can take decades for such work to be completed and to reach the state of a so-called greenfield site (where an NPP has been completely dismantled and the site has been released from nuclear regulatory supervision). In the case of a damaged NPP such as Fukushima Daiichi, dismantling is much more difficult.

TEPCO, the operating company responsible for the dismantling, faces three main challenges. These include the problem of radioactively contaminated water, which, however, affects the building complexes less and was already presented last week because of its special role. The other two challenges concern the reactor buildings themselves: On the one hand, the fuel assemblies of Units 1 to 4, which at the time of the accident were not sitting in the reactor pressure vessels (RPVs) but in the spent fuel pools, have to be salvaged. According to TEPCO, these fuel assemblies were not damaged by the earthquake and tsunami.

On the other hand, the so-called corium must be removed from reactor buildings 1 to 3. Corium is the mixture of molten materials that results from a core meltdown. This mass consists of nuclear fuel and the cladding tubes of the individual fuel rods, control rods, the materials of the affected parts of the reactor and their chemical reaction products with air and water. If the RPV is breached by the corium, molten concrete from the floor of the reactor building is added to the mass. In contrast to the fuel assemblies, which are still in the spent fuel pools, the corium has leaked out of the RPVs to varying degrees and reached the parts of the reactor buildings below.

In order to be able to start with the actual dismantling, first the necessary conditions had to be created. The site was completely devastated: Buildings were partially destroyed, electricity pylons snapped, and large parts of the plant site around the reactor buildings were covered with mud and debris. The clean-up work was severely hampered by the radiation; the site could only be entered with protective equipment, and remote-controlled machines were used in some cases.

Roadmap outlines the dismantling process in three phases

After the emergency services had brought the most urgent problems under control to some extent, thoughts turned to how to proceed with the Fukushima Daiichi nuclear power plant. Since repairing and recommissioning the destroyed Units 1 to 4 was out of the question, TEPCO agreed on a three-phase dismantling process with the Japanese regulatory authority NISA (since September 2012 Nuclear Regulation Authority – NRA). This is outlined in a so-called roadmap and extends into the second half of this century.

Reactor Units 5 and 6, which were not destroyed in the earthquake and the subsequent tsunami, are also included in the Roadmap. For a long time, it was unclear how to proceed with them. TEPCO finally decided on 31 January 2014 not to put them back into operation. Since then, they have been used e.g. to test new techniques for the investigation of Units 1 to 3. Otherwise, they are undergoing a "normal" dismantling process.

Recovery of the fuel assemblies from the spent fuel pools

Phase 1 of the roadmap started on 16 December 2011, when the then Japanese Prime Minister Yoshihiko Noda declared that the power plant had been brought to a stable state as planned ("cold shutdown"), and ended on 18 November 2013 with the recovery of fuel assemblies from the spent fuel pool of Unit 4. TEPCO undertook various construction measures shortly after the accident to improve the stability of the spent fuel pool in Unit 4. Subsequently, a so-called enclosure was erected over Unit 4. This enclosure (a steel scaffolding construction with sheathing) makes it possible to build up a negative pressure so that radioactive materials cannot escape into the environment and the reactor building is protected from weather-related effects. This also applies to similar enclosures that were erected above Units 1 and 3. Cranes and other equipment have also been or will be installed under these enclosures to allow the recovery of the fuel assemblies from the storage pools and later the retrieval of the molten nuclear fuel.

First, however, the various construction materials that fell into the spent fuel pools and onto the fuel assemblies during the explosions had to be removed. This was an extremely complicated process because, on the one hand, it was carried out remotely over many hundreds of metres and, on the other hand, it was absolutely necessary to avoid damage to the walls of the spent fuel pools during the removal of these materials because a leak would have caused the water to flow out and the cooling system to fail.

The recovery itself is basically a routine operation. Here, the fuel assemblies are pulled out of the storage rack with a fuel assembly unloading machine and lowered under water into a transport cask in a separate area of the spent fuel pool. An overhead crane lifts the fully loaded transport cask out of the water. After decontamination, the transport cask is taken to the central wet storage facility on the plant site. By the end of December 2014, all 1,533 fuel assemblies from Unit 4 had been retrieved.

The recovery of fuel assemblies from Units 1 to 3 is still ongoing. At the present time (25 February 2021), 553 of 566 fuel assemblies have been removed from Unit 3. In Unit 1, debris has been removed since January 2018, and a new enclosure will then be built here. In Unit 2, preparations are underway to construct a fuel assembly unloading machine. According to current plans, the last fuel assemblies at the plant are to be removed in the course of 2031.

Recovery of the corium

While the work on clearing the spent fuel pools has already progressed, the most difficult and lengthy task in the dismantling process still lies ahead: the removal of the corium from Units 1, 2 and 3. Unlike the fuel assemblies sitting in the spent fuel pools, it is very difficult to say exactly where this mass has been distributed in the reactor building. For this reason, research projects were started at an early stage, both in Japan and internationally, to clarify this question. A first approach was the use of special simulation codes that analyse the accident sequence inside the NPP and thus provide findings on the destruction on the reactors, the relocation of material inside the reactors, and the release of radioactive substances. GRS has also participated with its own research in various international projects of the Nuclear Energy Agency of the OECD.

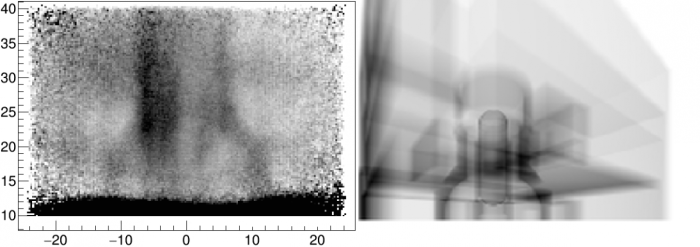

In order to gain information about the distribution of the corium, muon tomography was also used. In this process, cosmic elementary particles provide a kind of X-ray image of the inside of the reactor. While such research could not answer detailed questions about the situation inside the units, it did provide the first usable images with which the material distribution could be roughly identified. This agreed relatively well with the results of the simulation tool used by TEPCO.

However, the most important tools were endoscopes, remote-controlled robots and probes that provided direct images from the reactor units. The first images were taken at the beginning of 2012 with the help of endoscopes that were guided into the containments of the units via pipes. In addition, the first measurements of water level, temperature and dose rate could be obtained from the sensors carried along. However, the endoscopes are severely limited in their range of movement and can only provide selective images and data.

Special robots developed and adapted for Fukushima

Remote-controlled robots, which can reach into areas of the building that are inaccessible to the emergency services due to the high radiation levels, allow for more extensive recordings – although even in some cases, shielding against the radiation had to be erected for the operating personnel sitting at a distance. During the exploration work, very different types of robots were used, for example the caterpillar-like "Crawler", the military robot "Packbot", and also a remote-controlled boat.

Some of these robots were specially developed for use in Fukushima, others were adapted to the conditions. Here, too, the high level of radiation caused problems; the strong gamma radiation in particular can gradually destroy normal electronic components. The problem is known from robots that explore Mars and are exposed to similarly high gamma radiation there. Chip technology developed for such applications is also used at Fukushima. But even radiation-hardened robots reach their limits with the sometimes enormously high local dose rates in the reactor buildings (up to 530 sieverts per hour – that is about a billion times higher than the natural background radiation in Germany).

The different robots can be used to visually inspect the reactor buildings and create something like radiation maps of the respective units. The water level inside the torus of Unit 2 could also be measured with the help of an ultrasound measuring device. In addition to collecting visual impressions and measurements, one of the robots was also used to examine the composition of molten material underneath the RPV. With its gripper arms, it scanned material in several places that could be corium.

Dismantling delayed

According to the original plans of the roadmap, the molten nuclear fuel was to be recovered under water using remote handling equipment. The containment vessels were to be flooded before recovery began in order to shield the gamma radiation emitted by the nuclear fuel.

Based on the current state of knowledge, this concept must be reconsidered. Therefore, the recovery of the nuclear fuel is currently the subject of investigations and depends on the inspection results inside reactors 1 to 3. Various methods are being investigated, ranging from full submersion of the containment and partial submersion to dry containment. Currently, TEPCO is leaning towards partial submersion and access from the side at the bottom of the containment to recover the corium from the RPV bottom. Recovery from the top with the containment flooded is considered difficult because it would require sealing the containment leaks and could compromise the seismic stability over the long period of the recovery process. It is assumed that not all leak locations are known yet.

At the beginning of 2021, however, very high radiation levels were measured on the concrete shield plugs of the containments of Units 2 and 3, which put an end to the plans for the time being. Presumably, larger amounts of radioactive caesium-137 have been deposited there. The Japanese supervisory authority NRA therefore expects significant delays. The plan to start salvage operations in the spring of this year has been additionally delayed because of the coronavirus pandemic; for example, a robot gripper arm ordered in the UK could not be delivered on time.

In any case, it will take several decades before the dismantling of the Fukushima Daiichi NPP can be completed. The roadmap foresees about 20 to 25 years for the recovery of the nuclear fuel, after which more years of dismantling work will drag on until the greenfield state is reached. However, it is also being considered to dismantle the reactor buildings only above ground and to leave the underground parts of the buildings behind. Decommissioning should then be completed by 2051.

Please have a look at "Part 1: Accident sequence - Milestones of a disaster" and "Part 2: Radiological Consequences" of our series "10 Years of Fukushima" as well.

Find out more

GRS: Fukushima Daiichi 11. März 2011 – Unfallablauf | Radiologische Folgen. 5. Auflage 2016. https://www.grs.de/sites/default/files/pdf/grs-s-56.pdf [accessed on 27 January 2021].

GRS: Unfallablauf- und Quelltermanalysen zu den Ereignissen in Fukushima im Rahmen des OECD/NEA BSAF-Projektes Phase II. 2018. https://www.grs.de/publikationen/grs-485 [accessed on 27 January 2021].

TEPCO: What is the Decommissioning Project? https://www.tepco.co.jp/en/hd/decommission/index-e.html [accessed on 28 January 2021].