AnTeS - Analysis and test system for digital instrumentation and control (I&C) systems in nuclear installations

I&C in nuclear facilities includes all electronic measuring, control, regulation or monitoring equipment. Together with the operating personnel, they thus form the "central nervous system" of a nuclear power plant. Operational I&C systems take over automated control functions and support the operating personnel in performing their tasks. The main task of safety I&C systems (e.g. reactor protection systems), on the other hand, is to automatically trigger suitable protective functions in the event of problems or safety-relevant events, such as the shutdown of a reactor.

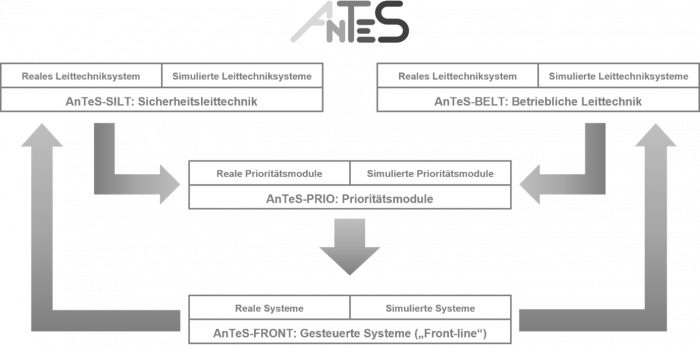

Many safety-relevant components in nuclear installations are controlled both by safety I&C and by operational I&C. Wherever this is the case, reliable prioritisation of the corresponding signals from the different I&C systems must take place. This function is fulfilled by so-called priority modules, which have a special safety significance as "bottlenecks".

Internationally, digital I&C systems are now mainly used for new build and for retrofitting of existing nuclear installations. In addition to many advantages, the use of digital I&C has also brought new challenges. Programming errors, faulty software updates, possible gaps in IT security and comparatively little operational experience make their evaluation difficult. As a result, a broad field of research has emerged in recent years, in the environment of which AnTeS was also first developed.

GRS has been developing AnTeS at its location in Garching near Munich since 2017. The modular platform makes it possible to study various issues relating to digital I&C systems. GRS uses and validates this tool in various national and international research projects.

Real I&C meets simulations

AnTeS has a modular structure. In addition to a real safety I&C system and a real operational I&C system, GRS also has easily configurable and flexibly adaptable simulations of generic I&C systems (safety or operation). If required, real and simulated priority modules as well as real and simulated controlled systems can also be used. All of these modules can be combined with each other as required.

The real safety I&C system and the real priority modules of AnTeS are based on the Teleperm-XS platform developed by Framatome, the corresponding real operational I&C system is based on the Simatic S7 developed by Siemens. As real systems, a test stand provides pumps, valves, drives and measuring sensors as they are also used in nuclear power plants. With the help of software developed by GRS itself, more complex systems can also be simulated and connected to the I&C systems (e.g. research reactors).

I&C – a topic of research at GRS

Since the mid-1990s, GRS has been working on digital and software-based I&C in nuclear installations. Prior to that, GRS experts had already been dealing with analogue, hard-wired I&C for many years. The focus of their work is the continuous further development of methods for assessing the reliability of modern I&C systems according to the state of the art in science and technology - as is the case with AnTeS. Further focal points of GRS's work are the evaluation of national and international events related to I&C, the evaluation of operating experience, and the assessment of new I&C systems.

In addition, GRS participates in the drafting of rules and regulations and discusses the requirements for digital I&C at national and international level on behalf of the Federal Environment Ministry - among others in the Reactor Safety Commission (RSK), the Nuclear Safety Standards Commission (KTA), the International Atomic Energy Agency (IAEA) and in projects of the European Commission.