WinLeck

As part of safety analyses for nuclear power plants it is to be demonstrated that leaks in pipes carrying coolant are safely controlled and managed. In order to be able to realistically describe the consequences of such leaks, especially with regard to the cooling of the reactor core, the quantity of the escaping coolant must be predicted as accurately as possible. With WinLeck, GRS calculates these leakage rates, taking into account all relevant influencing factors.

Starting point of many accident scenarios: Loss of coolant due to a defective pipe

Safety analyses are performed, among other things, to determine the consequences of accidents that involve a loss of coolant. They are based on the assumption that the leaks occur in safety-relevant and pressurised pipes or vessels are assumed. This approach is justified by the fact that – despite the proven high manufacturing quality of the components and extensive inspections – such events cannot be precluded.

To calculate the exact accident sequence, precise information is needed on how much coolant is leaking from the system. On this basis, it must be demonstrated that the safety systems are able to ensure the cooling of the reactor core with the injection of additional coolant. In the case of crack-like leaks, it is of interest whether the resulting leakage rates are large enough to be detected by the leak monitoring system before leak growth can take place and possibly lead to pipe rupture. This issue is addressed in the so-called leak-before-break concept.

The determination of leakage rates is also possible for concrete structures and gases.

WinLeck calculates leakage rate as a result of diverse and complex processes

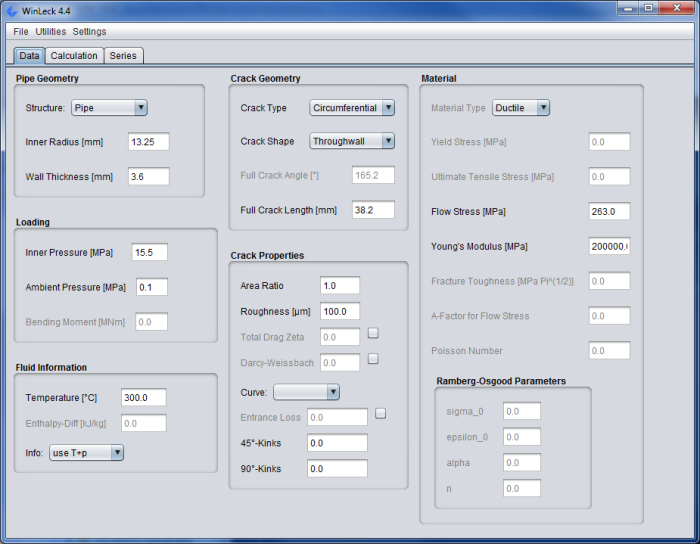

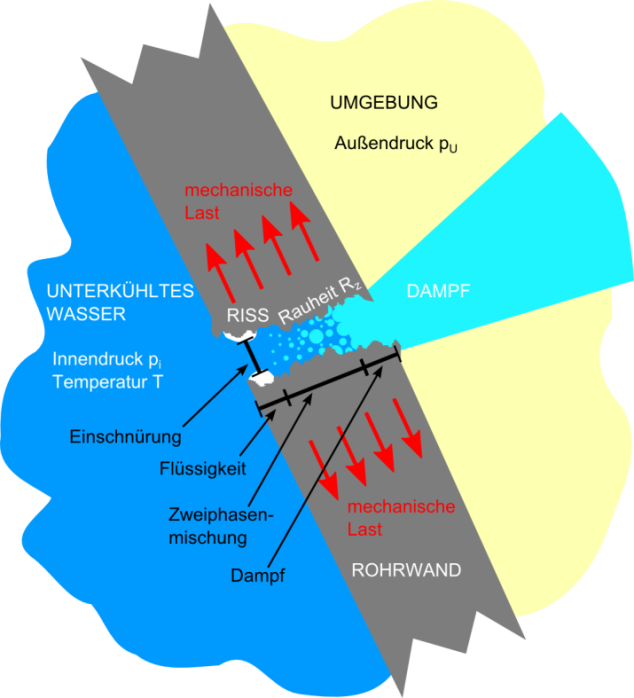

The WinLeck simulation code developed by GRS calculates leakage rates in three steps. In a first step, the leak area is determined on the basis of the acting mechanical loads and specific material properties. In a second step, the flow resistance for the outflowing fluid is calculated. This is mainly determined by the shape and surface properties of the crack channel, which in turn depend on the damage mechanism (e.g. corrosion, fatigue). Based on this, the flow rate is calculated in a last step, taking into account the exact fluid behaviour (constriction, pressure drop, evaporation and turbulence) (see Fig.). For the calculation of the leak area or leakage rate, several calculation models are available in WinLeck, which were developed by different institutions, including GRS. Thus, different calculation approaches can be compared with each other and uncertainties can be quantified.

Validation and application

The models used in WinLeck had been subjected to extensive validation. For the validation of the models for the calculation of the leakage (third step) alone, more than 1,800 individual measurements of leakage rates have been referred to so far.

The simulation code is used in particular for investigations into the leak-before-break behaviour of a pipe or vessel. For the demonstration of break exclusion, a minimum leakage rate is calculated and it is checked whether this can be detected with the existing leak monitoring system. Furthermore, WinLeck can be coupled with the thermal hydraulics code ATHLET (part of the GRS code system AC2).

WinLeck is not only used by GRS but also by other research institutions in Germany and abroad.

Use of WinLeck for gas pipelines and drinking water pipes

The prediction of leakage rates in pressurised pipes and vessels can help to assess and ultimately minimise safety risks in many technical facilities also in the non-nuclear field. For example, GRS used WinLeck to investigate the influence of flow resistance in the case of leaks in drinking water systems, thus making previous assumptions more precise. In principle, the application of the tool is also conceivable e.g. to calculate leakage rates for gas pipelines.