Piecing together the accident sequence – Interview with the Containment Department Head of GRS

The scientists have been dealing with the Fukushima Daiichi reactor disaster since the day of the accident on 11 March 2011. One of the experts in this field is Dr Martin Sonnenkalb. To put it simply, he and his team are dealing with the processes that take place in the containment of a nuclear power plant during accidents and severe accidents. On the occasion of the 10th anniversary of the reactor accident in Fukushima, we talk to him about the extent to which accident sequence analyses performed with simulation codes can support the dismantling process.

Hello Mr Sonnenkalb. Recently, the Japanese nuclear supervisory authority said that the concrete shield plugs of two reactors in Fukushima Daichii were many times more contaminated than previously assumed. How is it that such surprises still await us ten years after the accident?

Since the final report of the NRA – which is the Nuclear Regulation Authority – will not be published until the end of March, I cannot contribute any details. But the fact is that a picture of the situation is being pieced together at great effort, slowly moving closer to the reactors from the outside before entering inside – by whatever means. The strategic dismantling plan for Fukushima Daiichi was to start dismantling one unit in 2020/'21. To this end, various methods of access to the reactor and the surrounding areas in the containment were explored, including access from above via the area of the room that would then be open. The fact that the concrete shield plugs above the containments of units 2 and 3, which then have to be removed, are more contaminated than previously known, is certainly a setback for the dismantling work – but the finding can also be seen as another piece of the puzzle that completes our picture of the accident sequence.

Speaking of the accident sequence: Why are detailed findings on this important at all? What matters is the status quo at the time of dismantling, doesn't it?

On the one hand, this is true, but on the other hand, there are also important reasons for knowing the accident sequence as precisely as possible. By analysing each of the affected and non-identical reactors, knowledge can be gained about the accident sequences that are individual despite the same initiating event. Only in this way, it is possible to develop adequate dismantling plans and procedures.

Furthermore, the findings are used to prevent the possible occurrence of similar damage at other plants in the future. The nuclear accidents at Three Mile Island in 1979 and Chernobyl in 1986 were also evaluated in the same way. In addition, there is a scientific interest in describing uncertain or yet unknown processes in accident sequences more precisely. Sampling of the fuel or the core melt, which is carried out currently and later during dismantling, also serves this purpose. To this end, the scientists formulate specific requirements for sampling on the basis of the analyses. A considerable number of findings with numerous surprising insights have already been obtained by TEPCO through targeted investigations at the reactors. These findings can then be used to further develop the simulation codes, for example by creating and incorporating models for newly recognised physical-chemical processes.

What are these simulation codes about?

Simulation codes are an important tool in reactor safety research. With the help of these codes, different scenarios within a nuclear power plant can be run through during design basis accidents and severe accident events. A severe accident similar to that at Fukushima Daiichi cannot be simulated in its entirety in a test facility, but individual sequences can: By putting together the “pieces of the puzzle” and with the help of the tools developed, one can then generate an overall picture, so to speak. Among other things, GRS has developed computer codes that simulate the fuel rod and core behaviour and the sequence of design basis accidents and severe accidents. These codes have been validated on the basis of experimental data from individual and large-scale tests and are successfully used in Germany and abroad. But if you can validate simulation codes with data from real accidents like Chernobyl or Fukushima Daiichi, that is very valuable for science – which of course does not mean that we as scientists are happy about it, quite the opposite.

You and colleagues in your department are dealing with Fukushima Daiichi within the framework of research projects initiated by the Nuclear Energy Agency of the Organisation for Economic Co-operation and Development, OECD/NEA. Could you describe this work in more detail?

The projects mentioned are mainly two large projects in which I participate together with other GRS colleagues: In the first project BSAF – the Benchmark Study of the Accident at the Fukushima Daiichi NPP – we, as well as the numerous international partners, have analysed the accident sequences in the nuclear power plant units at the Fukushima Daiichi site in Japan in detail with different simulation codes. On the one hand, this enabled us to better understand the course of the accident and provide advice on how the dismantling could be managed and what requirements are placed on the acquisition of information in this context. On the other hand, strengths and weaknesses of the individual codes could be identified, which we could then develop further when needed. The project, which consisted of two phases, started in 2012 and ended in 2018 (see final report in German language here).

The current research project ARC-F – the Analysis of Information from Reactor Buildings and Containment Vessels of Fukushima Daiichi NPS – builds on the results of BSAF with focus on the behaviour of radioactive fission products during accident sequences. Among other things, we carry out calculations on the accident sequences in units 2 and 3 using the simulation code AC² developed by GRS and its main components ATHLET/ATHLET-CD and COCOSYS. In addition, we deal with so-called back-calculations of the fission product release from the plant – so, we want to answer the question regarding the time-dependent release from the reactors on the basis of the radioactive substances that were detected outside the plant during and after the accident, for which we also back-calculate the radioactive decay chain. This, in turn, allows us to draw conclusions in a different way about what happened in the reactor cores during the accident, which is used to validate the accident analyses and answer open questions.

So you could say that the data from the accident help to improve the calculation models?

Correct, that is another goal of the OECD/NEA projects. The aim is to eliminate model deficits in the simulation codes as far as possible and to expand and improve the models. To this end, findings are used from the dismantling or from inspections inside the facilities by the Japanese organisations involved and the plant operator TEPCO. Each new inspection brings at least one new surprise, such as the discovery of a largely intact fuel assembly head in the space under the RPV (note: abbreviation for reactor pressure vessel) of Unit 2 in January 2018.

This part of a fuel assembly you are addressing was clearly visible in an image TEPCO had published of the inspection at Unit 2. To what extent does such data help in your work?

They influence our work in that they help to rule out certain accident scenarios, but also to substantiate certain assumptions. The discovery of the fuel assembly head in Unit 2 is one such example. That such relatively well-preserved structures are actually found outside the RPV in the containment had previously been considered rather unlikely because this requires a relatively large opening at the bottom of the RPV, which must have been resulted from the accident and through which this component must have escaped together with core melt without melting itself.

In principle, the same also applies to the findings of elevated readings regarding the concrete shield plugs above the containment vessels – that we can exclude or confirm postulated accident scenarios through such findings.

So new data and values are helpful for your codes. You have been to Fukushima several times. What is the benefit of such a visit for you if you actually only need the data and values? You don't generate them yourself, do you?

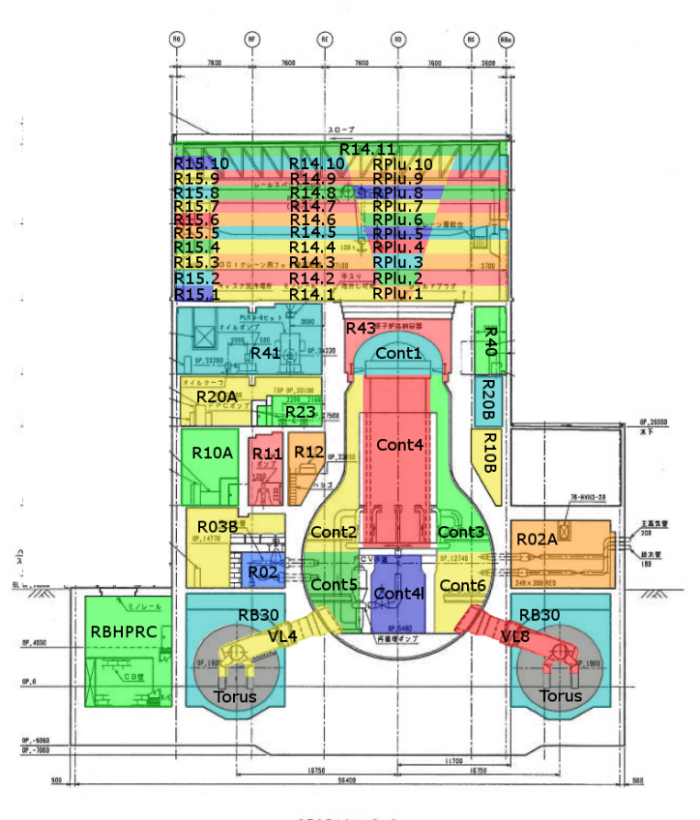

No, I don’t. As already mentioned, these are obtained by the Japanese organisations and the plant operator TEPCO, but such a visit can also be very important for our analytical work since plant details that may be important for the course of the accident cannot be obtained from studying plant documents alone. I am thinking of my visit to Fukushima Daiichi as part of the BSAF project: at that time we were able to inspect Unit 5, which is identical in construction to units 2 to 4 and had not been destroyed. Above all, we wanted to know what it looked like inside the containment, for example what the reactor looked like from below. We then spent two hours in the containment under full protection and got a spatial idea of the whole thing. That is really helpful when you later draw up your calculation model.

I first visited Fukushima Daichii some time before with an OECD expert group that was dealing with open issues in reactor safety research with regard to severe accidents. To be more exact, the issue of what information should be obtained from the dismantling of the facilities that can help us fill our knowledge gaps. We then had the opportunity to access the turbine building in Unit 1, of course in compliance with the massive radiation protection regulations at the plant site. The impressions of the massive destruction, the marks the water left that could be seen on the electrical switchgear cabinets at a height of two metres, the damaged entry gate and, of course, the many broken tanks that had been destroyed and shifted by the sea water, remain unforgettable to me. Even though you have seen it many times in photos, you really realise what forces were at work there as a result of the tsunami.

Such visits are of course something special; however, the majority of our work actually consists of working on and with the simulation codes.

And how does it actually work when you “feed” the simulation codes with new figures, data and facts?

We cannot really “feed” our computer codes with new information; it rather serves as a comparison to see whether our calculation results, which we have obtained by simulating the event, correspond to the measured values. You “feed” the code with figures at the very beginning, for example, when you digitally simulate the initial situation or the plant design by means of nodalisation of the rooms within the code. You then define values such as the size of the plant, the number of fuel assemblies or pressure and temperature specifications.

And to what extent do these codes still help in Fukushima today? What added value do the results from ARC-F offer when remote-controlled robots can now obtain real images and data from the reactor buildings?

First of all, as I said, these codes made it possible to work out an idea of the extent of the core damages. In principle, this has not changed until today, except that this idea is becoming more and more precise – and that certain sequences appear to be more probable, not least thanks to the robot recordings from inside the containments. I don't see the two technologies as competitors, but as complements. Just as the recordings and measurements make the simulation codes more accurate, the codes in turn help to classify and understand the recorded images and measured values, to put the puzzle together, so to speak. In addition, it has not yet been possible to take material samples from inside the reactors or from the core melt in the containments. The images and measured values must therefore be interpreted, for which the simulation codes provide the necessary tools.

And what happens to the simulation code when it is finished?

A simulation code is actually never completely finished. As a rule, these computer codes are always subject to further development – both through new findings, for example about the accident sequences in individual phases, and by adapting them to new reactor types. And as I already said, accident sequences with core degradation also involve a number of processes and phenomena that are not completely clear or also occur differently by chance depending on the circumstances, where we can close gaps, improve models and increase the informative value of the codes through new findings from dismantling or further experiments. A product ready for application is generally always available, it is then only further refined and improved – it’s the same as with other products, for example in the car industry.

Thanks a lot for the interview!