Repository safety: New shaft seal as geotechnical barrier

In order to dispose of radioactive waste safely, it must be stored in isolation from the biosphere. There is international agreement that a repository in deep geological rock formations offers the best conditions for this. The radioactive waste is to be placed in suitable repository casks in specially constructed mines deep underground. The safe isolation of the waste in such a deep geological repository is to be ensured by a diverse and redundant barrier system. This means that the barriers must be different in the way they function and independent of each other.

In repository research, a distinction is made between geological, engineered and geotechnical barriers. In simplified terms, the function of the geological barrier is assumed by the host rock - in Germany, there are the options of salt rock, argillaceous rock, and crystalline rock. The technical barrier is the waste container and any backfill materials surrounding it. These containers are placed in shafts in the host rock deep below the earth's surface. Subsequently, the remaining cavities must be backfilled and sealed, whereby a secure seal must be achieved over very long periods of up to one million years. These backfills and seals are called geotechnical barriers.

Sealing system of alternating sequence of segments

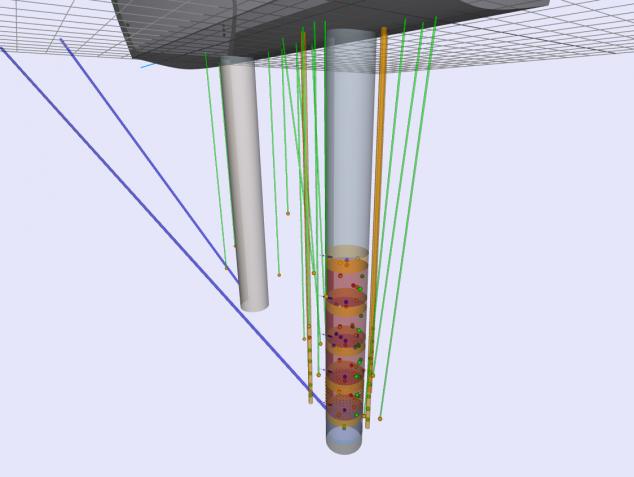

Various concepts for geotechnical barriers are currently being developed and tested by researchers. One such concept is the so-called "sandwich" sealing system. Here, after the radioactive waste has been emplaced and the cavities in the emplacement areas have been backfilled, the shaft of the repository mine is sealed by a vertical hydraulic sealing system. This sealing system consists of an alternating sequence of so-called sealing segments and equipotential segments.

The sealing segments are made of bentonite, which has a strong water-absorbing and swelling capacity. This is due to the fact that bentonite consists of 60 to 80 % of the mineral montmorillonite, which expands by many times its original size when water is added but retains a very low permeability. The 30-cm-wide equipotential segments ensure that the sealing segments are evenly moistened.

Large-scale experiment in the international rock laboratory

The sandwich system has already been tested on a laboratory and pilot facility scale, and the results were promising. Therefore, the main sandwich project started in 2019 as a cooperation of research institutions from Germany, Switzerland, Spain, Great Britain and Canada.

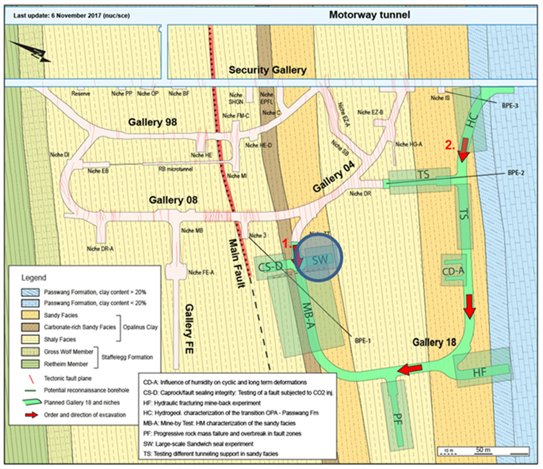

GRS is the technical leader of the project in cooperation with the KIT Competence Centre for Material Moisture, the developer of the sandwich sealing system. To test it on a realistic scale, a team of researchers is installing the sandwich sealing system in the international Mont Terri rock laboratory, which is located in a massif in the Swiss Jura mountains. The Opalinus Clay in Mont Terri is of particular interest to Germany: It resembles the South German Opalinus Clay or the North German Lower Cretaceous clays, which are possible emplacement formations in Germany, and is therefore well suited as a comparative object.

In such a large-scale in situ project, both the host rock and the respective conditions on site have an impact on the design of the sealing system. For example, different material mixtures are suitable for the material of the equipotential segments, depending on the host rock and the conditions on site. Klaus Wieczorek, technical director of the project, describes the objective as follows: "On the one hand, we want to test the materials determined on a laboratory scale and tested on a pilot facility scale in a realistic experiment; on the other hand, we expect to be able to better understand the physical-chemical process sequences through the experiment and to better predict the long-term behaviour".

System being tested in two specially sunk shafts

To this end, the research team first had to have two shafts sunk into the Opalinus Clay of the rock laboratory. For this purpose, they were provided with their own niche in the rock laboratory. With the help of a specially developed drilling rig, a 12-metre-deep shaft (Shaft 1) and a 10-metre-deep shaft (Shaft 2), each with a diameter of 1.2 metres, were drilled. Shaft 1 was equipped with a steel cage system and ladders so that the final experimental setup could be installed.

Before the actual experiment could begin, a number of other installations had to be made, as Klaus Wieczorek explains: "Since the function of the seal is to be tested by flooding the shaft, we first installed a hydration system. In order to obtain evaluable results, we also installed various measuring instruments. On the one hand, this instrumentation encompasses the sealing system itself, such as sensors for measuring water content, pressure and stress. On the other hand, external factors are measured, for example pore pressure changes in the rock or rock stresses." Afterwards, the shaft could be sealed with the sandwich system.

Shaft 2 will remain open for the time being. Next year it will also be fitted with a sandwich seal so that another experiment can be carried out again under slightly different conditions to obtain comparative values.

Flooding of Shaft 1 as milestone of the project

After the experimental setup was completed, the actual experiment began a few weeks ago with the flooding of the shaft. This step (in which only a small number of researchers could take part due to the coronavirus pandemic) can be seen as an important milestone in the course of the project. The water for the flooding is provided by the operator of the rock laboratory and brought to the sealing system from below via pressure chambers. These pressure chambers are filled in a controlled manner via inclined boreholes from the experimental niche, and the injection pressure is increased step by step.

In the coming months, the focus will be on monitoring the progress of the experiment and securing the data. As soon as the first data are available, they can be validated, evaluated, and interpreted. From the measuring results of the individual sensors, if necessary in conjunction with model calculations, the behaviour of the individual seal components and the overall system of seal and rock mass will be derived and evaluated. The aim is to prove the suitability of the sandwich system as a geotechnical barrier.

The project is supported and financed by the Federal Ministry of Economics and Technology. Its term ends on 30 June 2023.

Project highlights Disposal

Germany is searching for a site for a repository for high-level radioactive waste. According to the Site Selection Act, the site with the best-possible safety is be found by means of a comparative procedure. But how can the requirements of the law be transformed into concrete scientific requirements? Together with other institutions, GRS researchers now present a first approach.