Small-scale nuclear power plants: What's behind SMR concepts?

SMR definitions

Two definitions of SMRs are commonly used among experts. The International Atomic Energy Agency (IAEA) uses the term "Small and Medium Sized Reactors" to refer to reactors of small and medium size. Reactors with a capacity of up to 300 megawatts are referred to as small-size and those with a capacity of between 300 and 700 megawatts as medium-size.

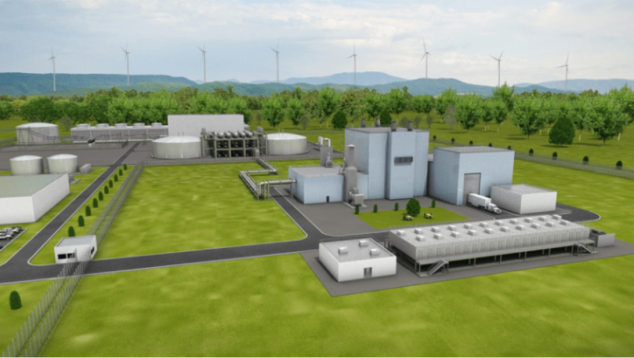

The second definition, which is more common today, was originally coined in North America. Here, SMR stands for "Small Modular Reactor". Compared to the IAEA definition, the underlying definition also takes into account the modular character of the plants. In concepts of this kind, it is envisaged that the essential components of a primary circuit are all contained in one single module. The idea behind this, apart from transportability, is to manufacture everything together in one factory and minimise the work on the construction site. Individual modules with low output can then be connected to form a larger power plant if required.

Previous SMR concepts

Previous SMR concepts can largely be grouped under the IAEA definition. They are mainly used to produce electricity in confined spaces, for example on icebreakers, submarines, or on aircraft carriers. However, small reactors have also been in operation on land for decades in some cases, e.g. several heavy water-cooled reactors in India. Most of the SMR concepts, however, are modified light-water reactors.

One example of a light-water-cooled SMR is the Akademik Lomonosov floating nuclear power plant, which has been supplying the remote port city of Pewek in Siberia and adjacent mines with electricity and heat since May 2020. CAREM (Argentina), which is currently under construction, is also a small-scale light water reactor.

Novel SMR concepts

Nowadays, the label Small Modular Reactors covers a large number of reactor concepts, some of which differ considerably from a technical point of view. The spectrum ranges from the scaled-down versions of existing nuclear reactor designs outlined in the previous section and the further development of older concepts that are not yet ready for the market to completely new designs for the fourth generation of nuclear power plants. In addition to electricity production and the modular character of the components, other aspects may be of interest. For example, due to their high core exit temperatures, some of the concepts are intended not only for electricity generation but also for the extraction of process steam or process heat for industrial applications. The use of transmutation to reduce radioactive waste, the breeding of fuel or the combustion of weapons-grade fissile material are also the subject of current SMR developments.

In addition, manufacturers hope for economic advantages in the use of factory-made SMRs, noting in particular lower investment costs, shorter production times and the possibility of serial production of individual modules. This should reduce licensing risks and construction delays and ultimately minimise any associated financial risks.

Different types of SMRs

In its Advanced Reactor Information System, the IAEA catalogues new reactor concepts, including SMRs, in terms of the coolant and moderator used. However, this classification does not do justice to all the special features of SMRs or new reactor concepts as a whole - developments such as those for thorium or high-temperature reactors are lost in the process. Nevertheless, a subdivision based above all on the coolant is a good idea:

1. Light-water-moderated and -cooled SMR concepts

This type of SMR is certainly the most long-standing and most widespread. A distinction is made here between boiling-water and pressurised-water reactors.

2. Heavy-water-moderated and -cooled SMR concepts

So-called heavy water contains the hydrogen isotope deuterium instead of normal hydrogen atoms. Deuterium absorbs fewer neutrons than light hydrogen. Instead of enriched uranium, natural uranium could therefore be used as fuel in heavy-water-moderated SMRs, but this is not done for reasons of efficiency.

3. Gas-cooled SMR concepts

Gas-cooled SMR concepts rely on the use of gases, such as helium or carbon dioxide, as coolants. Compared to other SMR types, they reach much higher coolant temperatures (up to 1,000 °C) and could therefore be used for the generation of process heat in the chemical or petrochemical industry. Low-temperature processes, for example for district heat utilisation, could be connected downstream with this concept.

4. Liquid-metal-cooled SMR concepts

In SMR concepts with liquid-metal cooling, lead, lead-bismuth and sodium are intended to be used as coolants. The metals are characterised by a high boiling temperature and a high heat capacity. Uranium in combination with plutonium or other transuranic elements will be used as fuel. To prevent contaminated primary coolant from reacting with the water-steam cycle, these concepts usually provide for an intermediate loop. The core exit temperatures should be around 750 °C. Steam and heat could then be decoupled in a temperature range of 500 to 700 °C for further purposes.

5. Molten-salt SMR concepts

Finally, other SMR concepts envisage molten salt both as a coolant and as a carrier for the fuel. It is assumed that the melts tested so far are stable at temperatures of up to 1,400 °C. Thanks to the heat transport properties of molten salts, it should be possible to build reactors with significantly smaller dimensions than gas-cooled reactors while maintaining the same power output. The high operating temperatures should allow high efficiencies as well as heat extraction for industrial high-temperature processes.

Novel SMRs and safety

Developers see safety advantages in new SMR concepts compared to large nuclear power plants. Among other things, passive safety functions, which are already partly used in existing nuclear power plants, are stated to be decisive for this. These systems do not require electrical energy for their activation and operation but are driven e.g. by gravity. In certain SMRs, passive safety systems are intended to allow automatic shutdown without the need for an external power supply or human intervention. Passive cooling should also be possible through gravity, convection and evaporation and thus without the use of electrically driven pumps to circulate the coolant. The latter, however, would in turn require a certain construction height.

By using alternative coolants and passive safety systems, certain accident scenarios that have to be considered in conventional nuclear power plants can be excluded in some SMR concepts. Also, the damage potential of an assumed severe accident is reduced compared to large nuclear power plants in that SMRs are to be loaded with significantly smaller quantities of nuclear fuel - the amount of radioactive material that could be released into the environment in the event of an accident is correspondingly smaller. However, these potential advantages are offset by new safety challenges - depending on the concept.

For the concept of a sodium-cooled SMR, for example, it must be ensured that the metallic sodium does not come into contact with oxygen, as it ignites easily. In addition, the highly corrosive effect of molten salts places special demands on the properties of the materials to be used, e.g. for the construction of the coolant lines. Finally, in the case of innovative concepts, the very limited operating experience compared to the classic light-water reactors must also be taken into account. Many of the safety improvements developed for light-water reactors are based on the evaluation of events. Corresponding empirical values are of course not available for a number of the new SMR concepts.

Work of GRS on SMRs

Within the scope of its own research and the work as an authorised expert organisation, GRS has dealt with the safety of SMR concepts on a conceptual level. In a study funded by the former Federal Ministry of Economics and Technology, for example, the need for research for the further development of existing simulation codes used for the assessment of the safety of nuclear power plants was examined, among other things.

An assessment of the safety of SMRs is only possible to a limited extent for various reasons. It is possible to make statements on whether a certain SMR concept is plausible in its safety-related design and complies with recognised principles. However, on the basis of concepts alone, no reliable statements can be made as to whether a plant constructed on the basis of the concept would be licensable according to the current state of the art in science and technology or according to the applicable rules and regulations.

Such assessments require a great deal of information that cannot be obtained from a concept alone or is not yet available. First and foremost, this includes the concrete technical implementation of the concept, e.g. the exact technical nature of the safety-relevant components and the materials used. However, the safety of a nuclear installation also depends e.g. on the characteristics of the specific site, e.g. with regard to seismic activity or possible flooding.