The shutdown of the last NPPs in Germany: a brief review from a (safety) technical perspective

The last three German NPPs: facts, figures and data

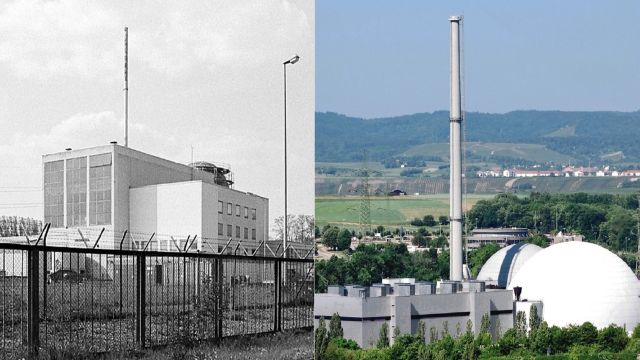

After several months in stretch-out operation, the three nuclear power plants (NPPs) Emsland, Isar 2 and Neckarwestheim 2 will now also be shut down. The shutdown of these so-called Konvoi plants, which were built in the late 1980s, marks the end of a good six decades of electricity generation from nuclear energy in Germany. During this time, 37 NPPs were operated commercially, the majority of them pressurised and boiling water reactors. By the end of 2022 they had produced almost 5,600 terawatt hours (TWh) of electricity. This corresponds to about 10 times the current total annual consumption in Germany (approx. 550 TWh in 2022 according to the German Environment Agency (Umweltbundesamt – UBA)).

In the 1990s, between 160 and more than 170 TWh were produced annually from nuclear energy. For comparison: large cities like Cologne or Munich today consume between 2 and 3 TWh per year. While the share of nuclear energy in the electricity mix was still around 30 percent in the 1990s, it was only 6.5 percent in 2022 with three NPPs still in operation. Since 2011, electricity production from nuclear energy has been steadily declining after the then Federal Government, supported by a broad social consensus, decided to finally phase out nuclear energy.

The beginnings: nuclear euphoria, nuclear ministry and failures

Driven by the worldwide euphoria for nuclear power as a clean and reliable form of energy in the 1950s – exemplified by the “Atoms for Peace” speech of the then US President Dwight D. Eisenhower before the UN General Assembly in 1953, or the founding of the International Atomic Energy Agency IAEA in 1957 – plans to enter nuclear technology also took shape in the Federal Republic of Germany. This led to the establishment of the Ministry of Atomic Affairs, which was headed by Franz-Josef Strauss, appointed as the first Minister for Nuclear Energy by the then Federal Chancellor Konrad Adenauer.

With the Kahl experimental nuclear power plant, the first NPP in Germany went into commercial operation at the beginning of 1962 after a construction period of only three and a half years. It was a boiling water reactor with an electrical output of 15 megawatts (MW). In the following years, various reactor types were built in Germany, some of which were based on own developments. These include, for example, a heavy water-cooled pressurised water reactor (MZFR Karlsruhe), a pebble bed reactor (AVR Jülich), a pressure tube reactor (Niederaichbach NPP), a superheated steam reactor (HDR Karlstein) and a sodium-cooled breeder reactor (SNR-300 in Kalkar).

The aforementioned reactor concepts were not pursued further in Germany for various reasons, whereby (safety) technical aspects also played a significant role in some cases. For example, the THTR-300 had only been in commercial operation for about two years, and the so-called fast breeder reactor in Kalkar was completed in 1985 after a project period of about 12 years, but never went into operation. Some of the concepts were taken up again abroad, albeit decades later. For example, a pebble bed reactor in China began commercial operation at the end of 2021.

Light water reactor technology from the USA

Instead, the light water reactor technology imported from the USA was adopted and further developed. The focus on light water reactors marked the beginning of a success story for nuclear technology in Germany from a safety perspective. Thus, German plants and the associated safety culture enjoy a high reputation among international experts. There have been relatively few reportable events with a significant safety impact in Germany. None of these events was classified as a “serious incident” (level 3) or higher on the IAEA's seven-level International Nuclear and Radiological Event Scale (INES).

Another indicator is the high availability of the plants. The prerequisite for this is that the plants concerned have to be taken off the grid as rarely as possible and, if necessary, only for as short a time as possible due to technical damage or safety-relevant events. The three Konvoi plants still in operation in Germany stand out in this regard: In the IAEA's Power Reactor Information System, the availability factor is stated at well over 90 per cent for all three plants – the long-term international average for availability is between 80 and 85 per cent. Moreover, German plants have been world champions in electricity production 23 times. This title could no longer be achieved in recent years since the plants, which were originally designed primarily to cover the base load, increasingly had to be operated in so-called load following operating mode to balance out fluctuations in the grid from the feed-in of renewable energies. To date, the Grohnde and Isar 2 plants are the only ones in the world that have generated an electricity volume of more than 400 TWh.

The good (safety) technical reputation of the KWU plants (Kraftwerksunion, today Framatome) was also reflected in exports to other countries: Units 1 and 2 of the Atucha NPP (Argentina) went into operation in 1974 and 2016, respectively, Unit 2 of the Brazilian Angra NPP in 2001, Unit 3 is to follow in 2026. In Europe, there are German-designed plants in Gösgen (Switzerland), Trillo (Spain) and Borssele (Netherlands) – the latter, which belongs to the PWR generation constructed before the pre-Konvoi plants, is to be extended for another 60 years until 2033 according to plans of the current Dutch government.

Looking back over the past decades of NPP operation, mainly three very different reasons can be identified for the positive balance from a safety point of view: the safety design of the plants and safety-oriented operation, thorough and effective supervision and strong expert committees, and the endeavour to continuously enhance nuclear safety by evaluating worldwide operating experience and safety research.

Design and safety

While the first plants in Germany (Kahl, Lingen, Gundremmingen A, Obrigheim) were still largely built according to US designs, German design prevailed with the Stade NPP in the early 1970s. Among others, Biblis A, the world's first 1,300 MW plant, was built during this time. The plants were not only characterised by a strong safety philosophy; the early use of certain materials, for example, also paid off. In Germany, for example, only the steam generators in the Obrigheim NPP, designed according to the US model, had to be replaced. In other countries it is quite common to replace these large components after about 20 years.

In addition, NPPs in Germany were not built in series, as is the case in France, for example. Thus, the experience gained from the construction and operation of the already existing plants could be transferred in the design of the subsequent ones. Only the Konvoi plants were designed as a kind of mini-series, but here too, there were minor adjustments. Especially the plants built by the former KWU are characterised by a robust safety design compared to other manufacturers. For example, they have a four-train safety system to control events where one train is under repair and another is unavailable at the same time. In addition, they house four large and four small emergency power diesels per unit. In comparable other Western plants there are only two emergency power diesels per unit. In addition to the continuous improvement of designs, the decision not to build many identical plants also offered an advantage that can be seen in the current problems of many French plants. There, only series construction has made it possible for faults in certain components to affect several plants at the same time.

Strong institutional safety culture

Another factor for the high safety level of German NPPs is the institutional safety culture in Germany, which has been established in the form of different authorities, expert committees and organisations. On the one hand, the federal structure of the Federal Republic of Germany plays a role here: with direct supervision by the Land authorities and federal supervision by the Federal Environment Ministry, there are two levels of regulatory control. On the other hand, the exchange of expertise in various committees has also contributed significantly to the goal of continuously improving safety.

As early as 1958, the Reactor Safety Commission (Reaktor-Sicherheitskommission – RSK) was established as a body of experts to advise the Federal Government on the extent to which the operators of nuclear facilities meet the requirements for the necessary precautions (damage and risk prevention) through appropriate equipment, organisation and management. When appointing the members, importance is attached to ensuring that the current state of the art in science and technology and the expertise from nuclear practice are bundled through the involvement of science, expert organisations as well as manufacturers and operators, and that the direct technical exchange is promoted.

In 1972, the Nuclear Safety Standards Commission (Kerntechnischer Ausschuss – KTA) was founded based on the model of the German Steam Boiler Committee (Deutscher Dampfkessel-Ausschuss – DDA). The KTA, which brings together experts from authorities, authorised experts and experts from operators and manufacturers, defines detailed safety requirements, the fulfilment of which ensures that precautions have been taken as required by the Atomic Energy Act. The KTA safety standards, which underpin the nuclear rules and regulations with the corresponding legal provisions, can be compared with the German DIN standards.

In 1977, i.e. at the peak of NPP construction, Gesellschaft für Anlagen- und Reaktorsicherheit (GRS), an independent technical-scientific research and expert organisation, was founded and has been acting since then as Germany's central expert organisation in the field of nuclear safety: on the one hand, as an expert for the Federal Government and, on the other hand, as part of its basic and applied safety research, developing, among other things, computer codes and methods for safety assessments by expert organisations such as the technical inspection associations (TÜVs).

Lessons learned from events in Germany and abroad

The third factor is the error culture established in Germany. The analyses performed by GRS play an important role in this respect. In this context, safety-relevant events in nuclear facilities in Germany and abroad are examined. The findings from these investigations – often also formulated in so-called information notices – formed the basis for numerous safety-related improvements, which also resulted in concrete technical developments and corresponding retrofits.

For instance, after the Chernobyl reactor disaster in Germany, both the filtered containment venting system (in Germany also referred to as Wallmann-Ventil, which translates as Wallmann valve, named after the then environment minister Walter Wallmann), which enables filtered venting of the containment in an emergency, and the so-called recombiners were developed, with the help of which gaseous hydrogen is oxidised to water with surrounding oxygen, whereby hydrogen explosions can be prevented in the event of accidents with cooling failure. These are both safety-related innovations that could have significantly mitigated the progression and radiological effects of the Fukushima accident had they already been implemented in the plants concerned. Recombiners from Germany have been delivered to more than 200 plants worldwide to increase the safety level on site. Other events from which improvement potential for German plants could be derived are, for example, the hydrogen explosion at the Brunsbüttel NPP (2001), the approximately 8,000 incorrectly placed dowels in the two units of the Biblis NPP (2006) or the transformer fire at the Krümmel NPP (2007).

Important impulses for further improving nuclear safety also came from Germany at the level of international organisations and committees. For example, experts from Germany – also building on corresponding research work of GRS – were significantly involved in the development of recommendations for so-called “Severe Accident Management Guidelines” within the framework of the IAEA.

Use of nuclear energy in the GDR

Nuclear power plants were also operated in the GDR at the Rheinsberg and Greifswald sites. These were reactor types of Soviet design, the so-called water-water energetic reactor (WWER or the Russian abbreviation VVER for Vodo-Vodyanoi Energetichesky Reaktor). In Rheinsberg, a WWER-70 with a capacity of 62 MW fed into the grid from 1966, followed six years later by a first-generation pressurised water reactor in Greifswald. A total of four WWER-440 units were operated here, another one (Unit 5) was being commissioned at the time of reunification, and three more units were under construction.

The plants in Greifswald and Rheinsberg were taken off the grid in 1990 due to safety concerns. The basis for the decommissioning of units 1 to 4 of the Greifswald NPP was, among other things, the safety assessment by GRS.

Outlook

Even after the shutdown of the last three German NPPs, there will still be a need for strong safety expertise in the field of nuclear technology in the long term. There are many reasons for this. In Germany itself, the safety of the dismantling of all decommissioned NPPs and the operation of the storage facilities must be ensured – the latter probably for many decades to come. In addition, research reactors continue to be operated in Germany. In view of the numerous foreign NPPs operating in the European neighbourhood, a long-term task is also to maintain emergency preparedness and response in Germany at the highest level. This requires continuous safety research – for example, when it comes to being able to simulate possible accidents and their radiological consequences for Germany as realistically as possible – as well as the best possible knowledge of the concrete technical design of these plants. This aspect is becoming even more important due to the plans of a number of European countries to build new NPPs or extend the operating lives of existing ones, especially since new concepts are also to be realised there in some cases. And finally, strong technical and scientific expertise is needed if relevant impulses for improving safety are to continue to come from Germany in the future – in the form of safety-promoting rules and recommendations, as formulated at the IAEA or EU level, but also, if necessary, in the form of concrete technical concepts for safety-related retrofits.